Miatech Bio Turbo

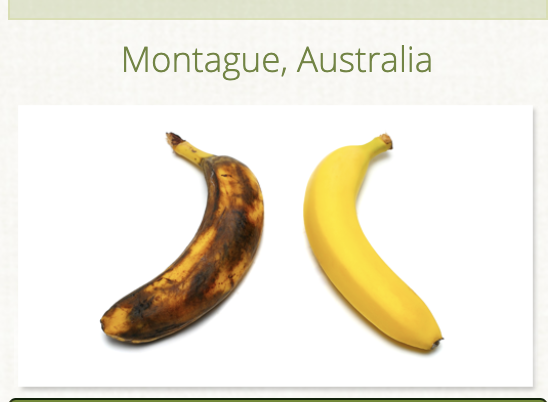

The Bio Turbo system is used extensively throughout the world to ensure optimal quality of the produce when held in cool storage and being sent on to the next link in the cold chain.

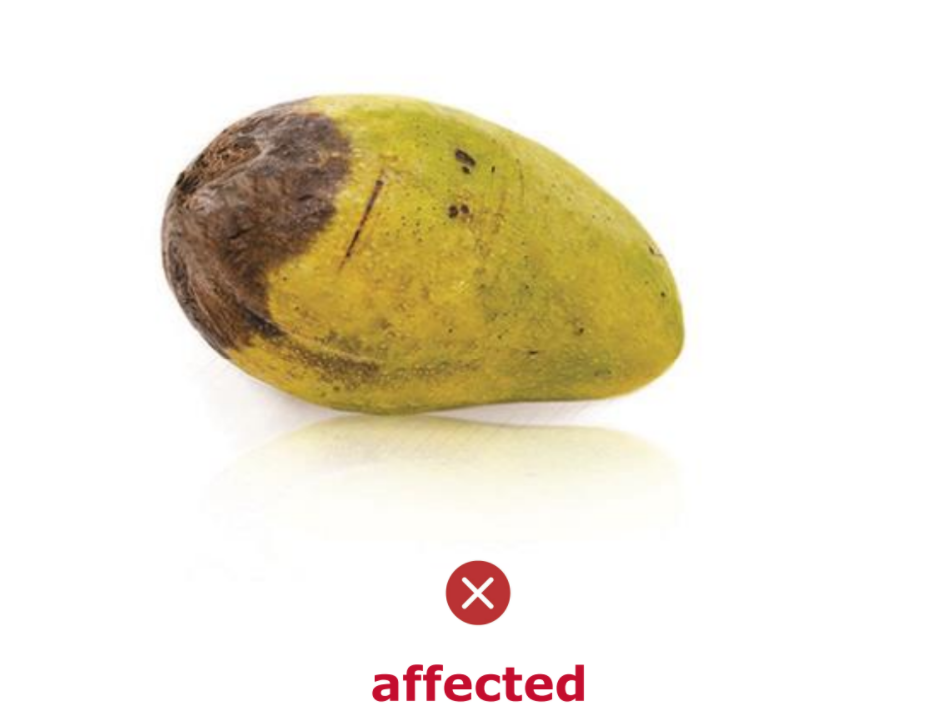

Bio Turbo is easy to install and removes ethylene and airborne pathogens from the environment, prevents the process of premature ripening to ensure longer shelf life and reduction in produce spoilage.

If you are storing ethylene sensitive products with ethylene producing products in the same cool room the Bio Turbo is the solution to prolong shelf-life, quality of produce keeping your operations profitable and driving customer satisfaction.

• Extends Storage Life

• Removes Ethylene

• Kills Bacteria & Viruses

• Prevents Mold & Fungi Build-up

• Decreases Odours & Cross Contamination

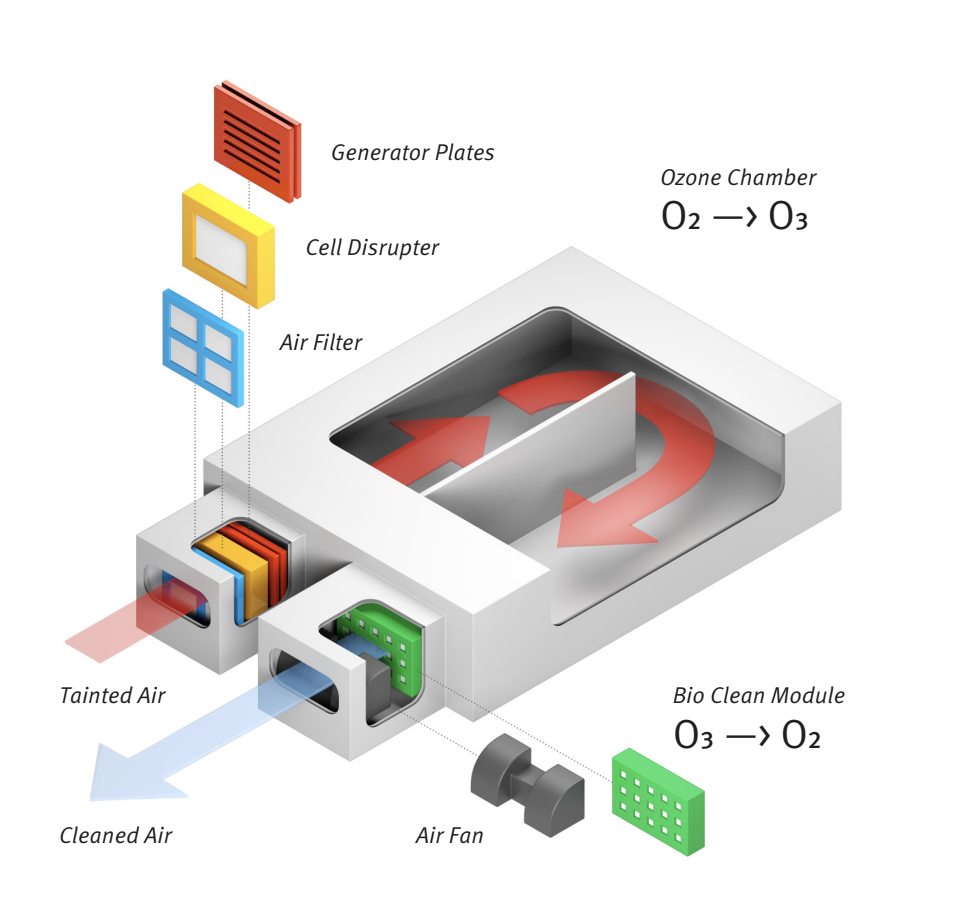

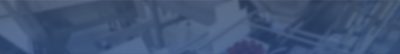

THIS IS HOW IT WORKS:

STAGE 1: AIR FILTER

The air filter removes dust and visual particles from the air.

STAGE 2: CELL DISRUPTER

An anti-microbial chemical is applied to the surface of a specially designed

disrupter. It works by rupturing the outer membrane of the cells that make up

these airborne pathogens. With efficiency rates of 99.5%+, this process stops

their normal life development, thus destroying the cells.

STAGE 3: OZONE CHAMBER

This chamber uses the positive effects of ozone to eliminate ethylene gas. The

ozone is safely contained within this chamber and not dispersed throughout

the storage area.

STAGE 4: BIO CLEAN MODULE

In this final stage, a catalyst is used to change the ozone into clean oxygen. The

catalyst creates a reaction that breaks down the ozone molecule. From here the

clean oxygen is released back into the environment.